Impact for Diemakers

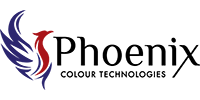

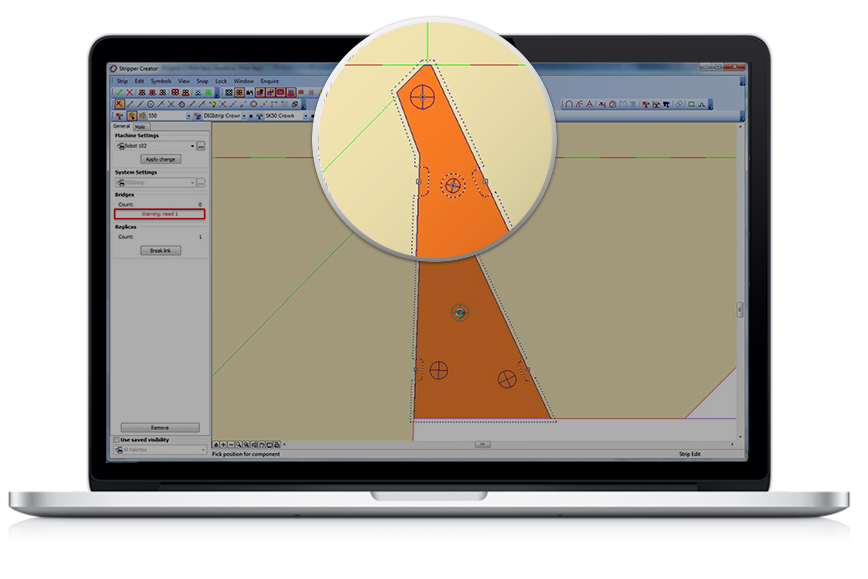

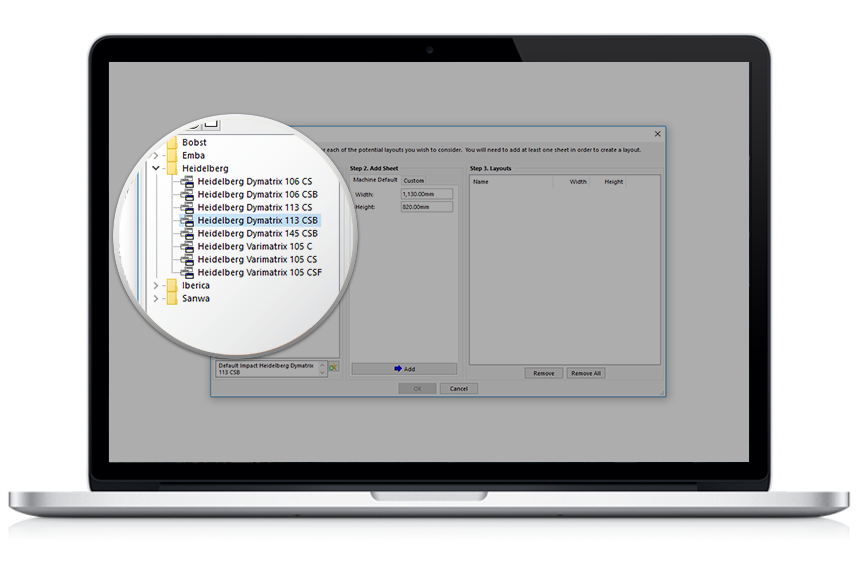

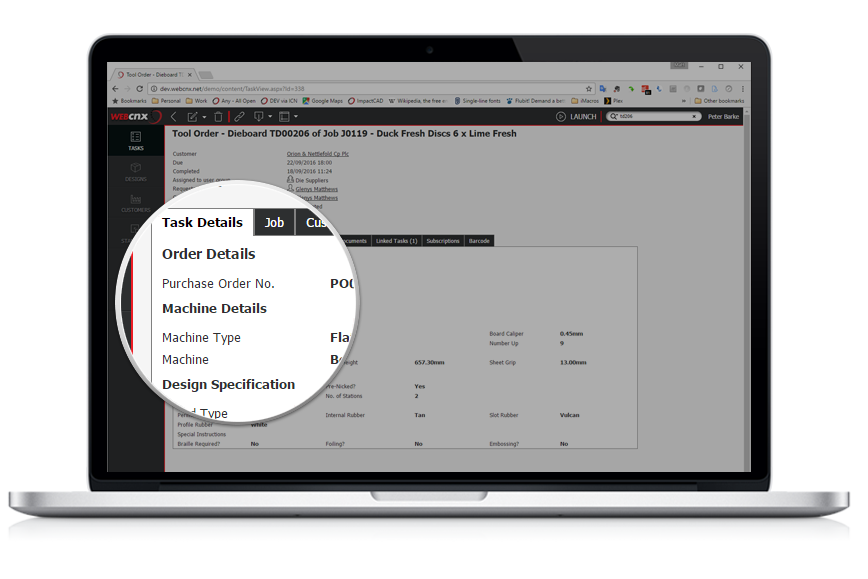

We have used our in-depth industry knowledge to make Impact CAD the world’s leading software package for die-makers. From customisable templates to pinpoint manufacturing, the software is shaped around your business and way of working.